Experience seamless integration with CSEM VISARD

Contact us today to request a demo and discover how our platform can optimize your production processes.

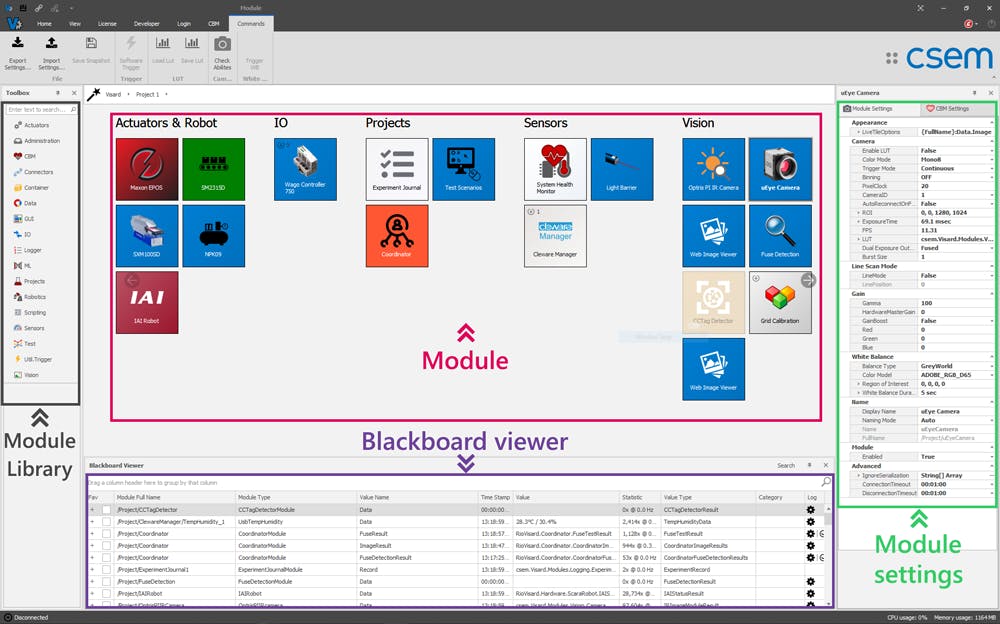

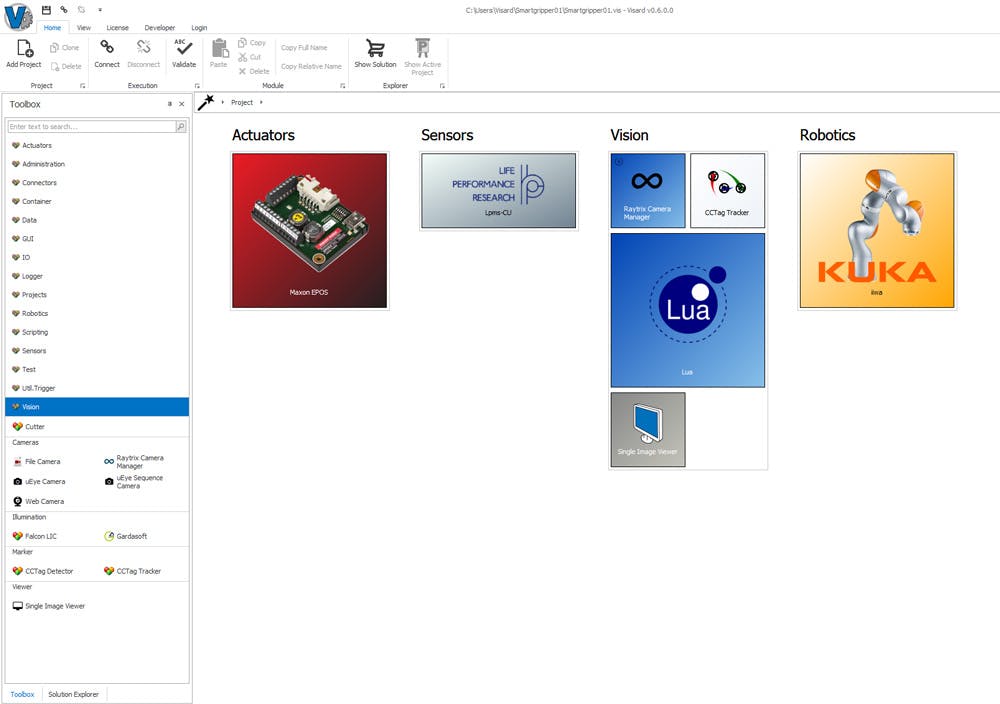

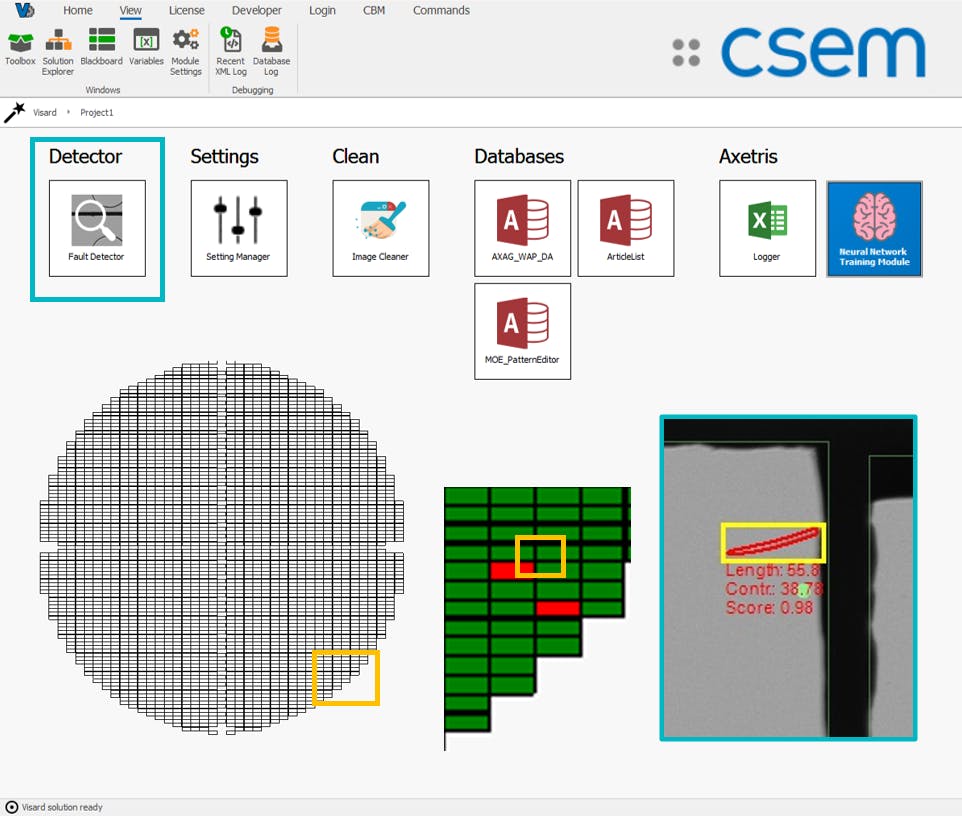

CSEM presents a vertical process integration platform: VISARD – Vision Automation Robotics Designer. It supports plant operators in the rapid commissioning of complex, sensor-guided production systems. The platform provides a user-friendly, industry-compatible tool for integration.

CSEM VISARD enables:

The first goal of VISARD is to support plant operators and integrators in their daily work: Plants today consist of a confusing number of proprietary components, most of them requesting highly specific interfaces. Both plant integration and connection to the company's own control systems tie up resources of highly qualified personnel.

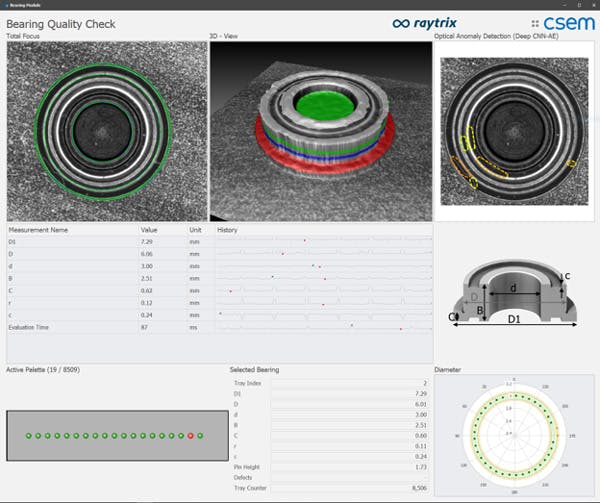

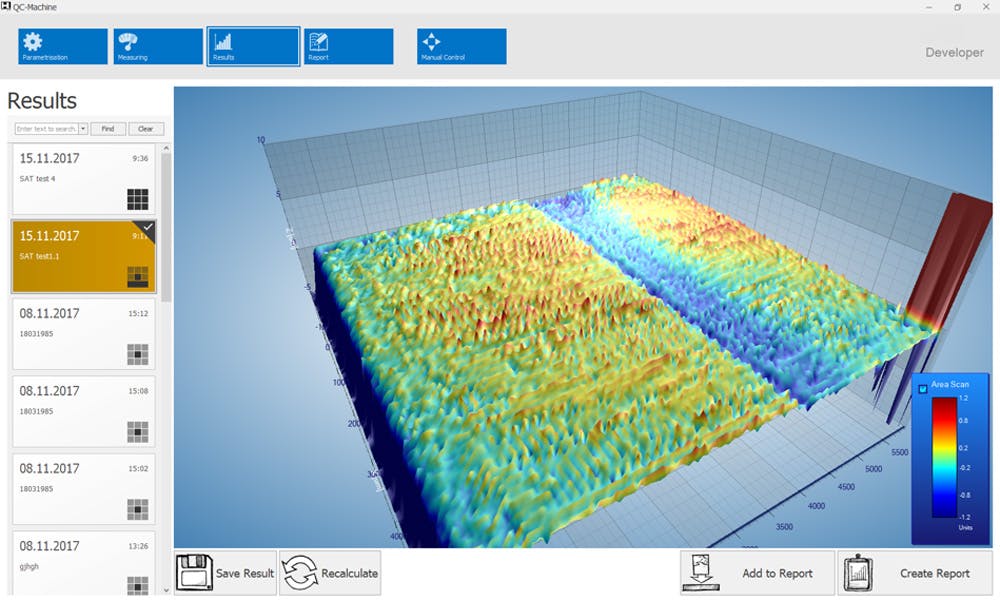

The second goal of VISARD is to simplify access to modern sensor systems and mathematical analysis concepts. Today, production systems and processes are continuously monitored and recorded by sensors. Keywords "condition monitoring" and "predictive maintenance". Sensors and data analysis cannot be separated from each other, and optimal use is a high hurdle even for experts. VISARD therefore integrates the tools for sophisticated data analysis, which are increasingly becoming state-of-the-art.

This is where VISARD comes in: VISARD provides a PC-based, manufacturer-independent, easy-to-use software environment for heterogeneous system integration that is compatible with industrial needs. Its use is intuitive and requires no programming knowledge.

Contact us today to request a demo and discover how our platform can optimize your production processes.