Reach out to us today!

Let's collaborate to turn your concepts into reality using our precision-driven technology to propel your projects to unprecedented heights.

Discover compliant mechanisms, also known as flexure mechanisms, which underpin our expertise in systems engineering developments for precise instruments.

(Dieser Artikel ist nur auf Englisch verfügbar)

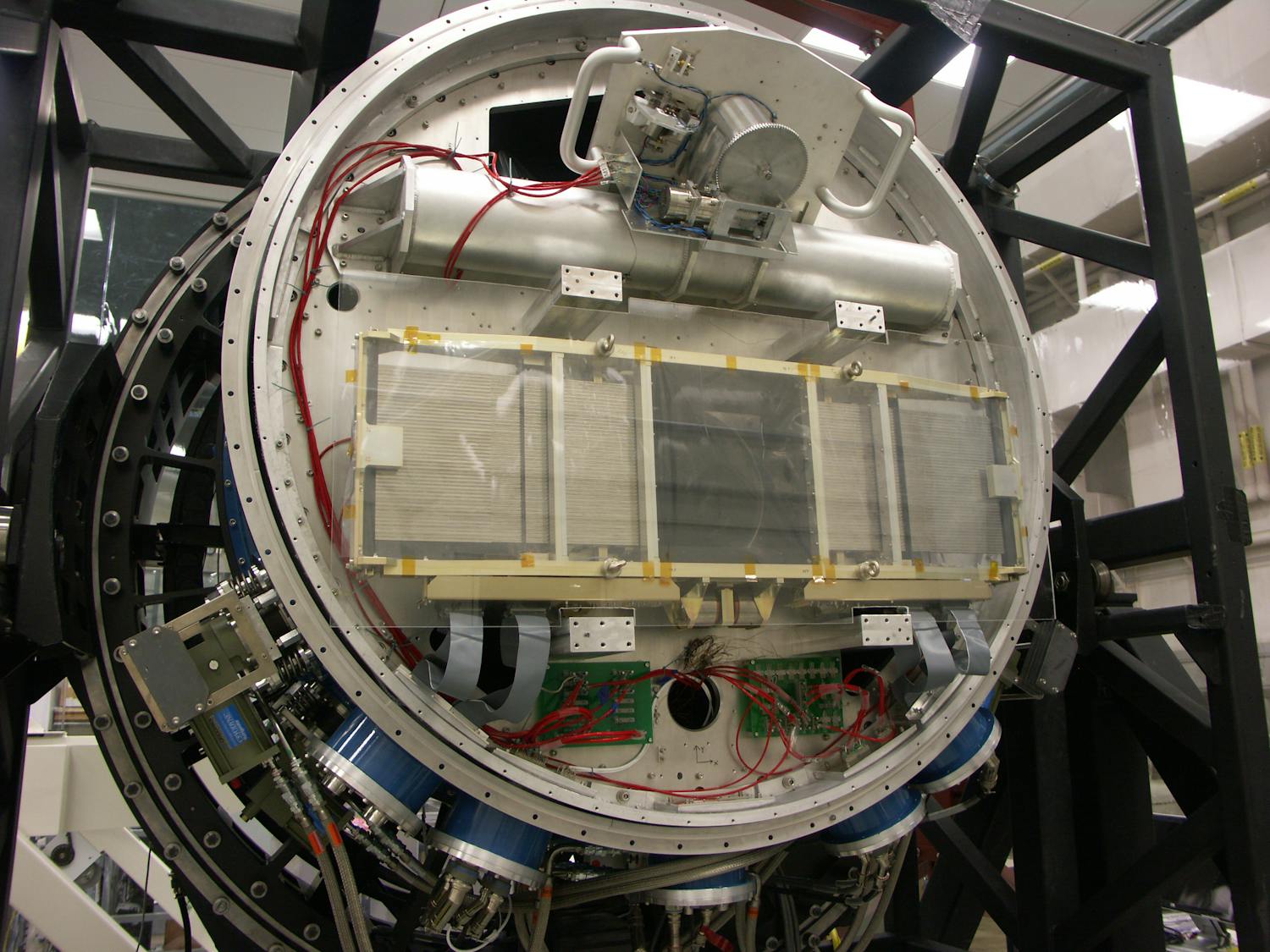

At CSEM, we excel in developing, assembling, and testing comprehensive systems with submicron precision. Our team specializes in multiphysics simulations, advanced control, electronics, and optics, meeting the demanding requirements of space-oriented and scientific instrumentation.

With an extensive legacy of 35 years, our design of flexure mechanisms allows them to survive in harsh environments—spanning space, vacuum, cryogenic, and vibratory settings. Our imprint on the Swiss Space Policy highlights our ability to craft intricate mechanisms to serve the pursuit of space and science.

Esteemed instruments such as MOSFIRE at the Keck Observatory, SOFIA the airborne observatory, IASI onboard Meteosat, InfraRed Sounder (IRS) on Meteosat Third Generation (MTG), CLUPI focus mechanism for EXOMARS and numerous others reap the rewards of our friction-free technology. Our mechanisms secure enduring longevity and unwavering reliability, influencing the course of technological excellence.

At the forefront of innovation, we harness the power of additive manufacturing to transform mechanisms. This groundbreaking approach allows us to integrate electrical conductors and sensors into mechanisms, pushing the boundaries of functionality and performance.

CSEM’s precision expertise reverberates across diverse sectors and research realms. Our collaborations span beyond conventional bounds, encompassing industries and institutes alike. Our precision-focused capabilities extend beyond small-scale instruments. From large-scale industrial tribometers that conquer extreme conditions to automated dispensing machines engineered to perform flawlessly in harsh conditions, our co-innovations help drive progress with unwavering determination.

By tapping into our systems development expertise alongside MEMS capabilities, we propel impactful innovation across a diverse range of sectors, making significant strides in aerospace, watchmaking, metrology, and the field of medicine.

Let's collaborate to turn your concepts into reality using our precision-driven technology to propel your projects to unprecedented heights.

Explore our groundbreaking research and technological developments that have propelled advancements in space-oriented tools and scientific instrumentation: