May 2, 2022

Plastics get a unique digital watermark

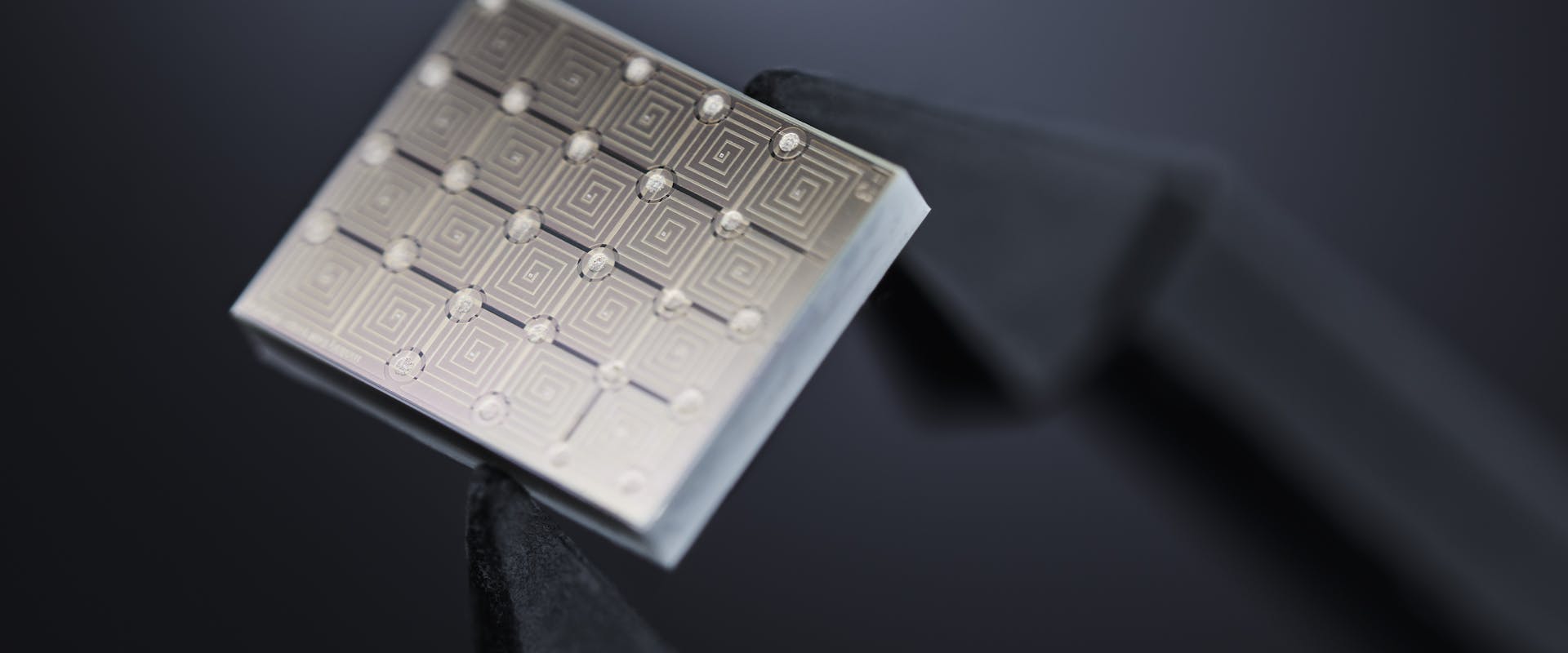

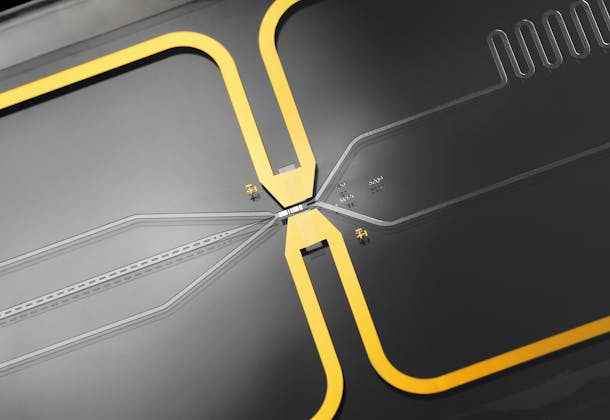

CSEM worked with matriq AG to develop an innovative marking technology for plastics called DynamicMold. Together, they manufactured a MEMS micro-heating system that applies data matrix codes directly onto plastic components during molding.