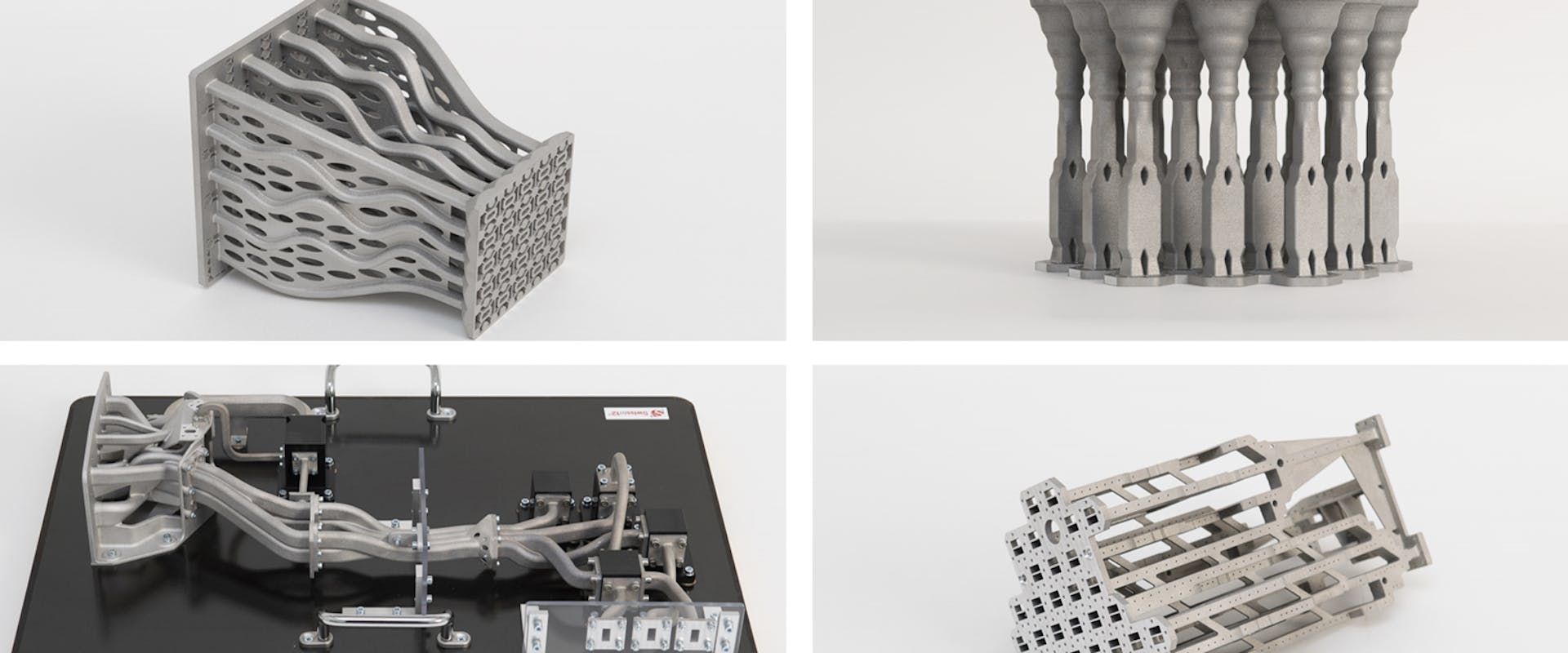

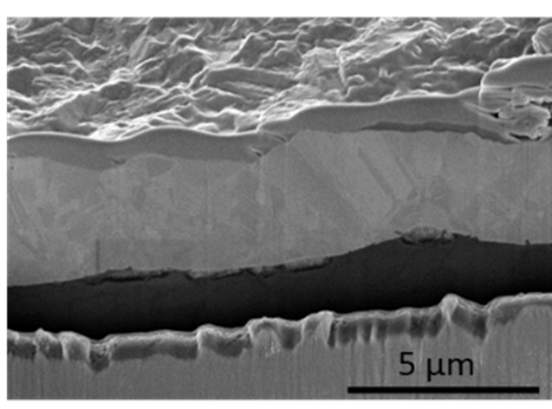

Swissto12 and CSEM have been collaborating for over four years to develop metal plating processes adapted to 3D printed parts. Thanks to its expertise in surface engineering and chemistry, new proprietary surface treatments and electroless processes have been developed to produce highly adhesive and conformal coatings on 3D-printed polymeric or metallic materials. CSEM is currently developing a customized electroless silver plating process enabling conformal coatings of 3D-printed surfaces to up to 10-micrometer thickness.