Pushing the boundaries of flow measurement and control

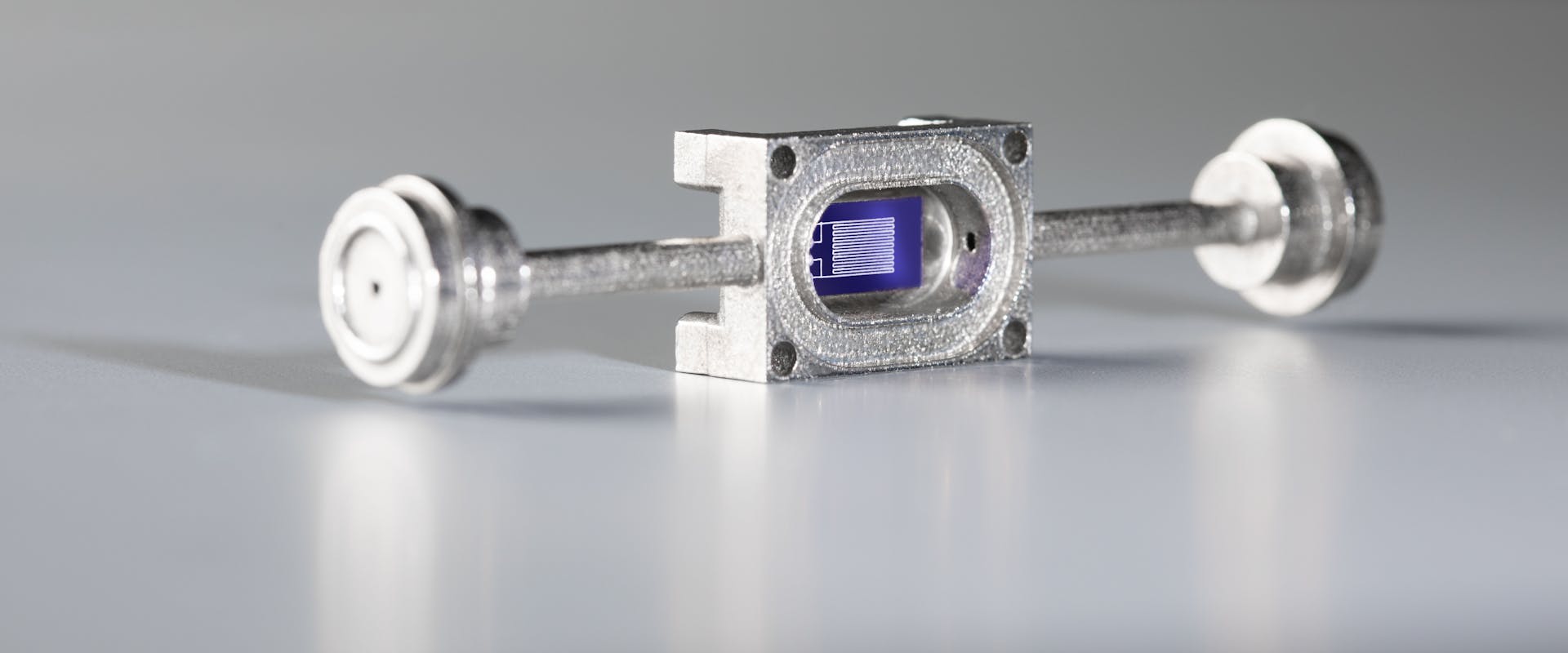

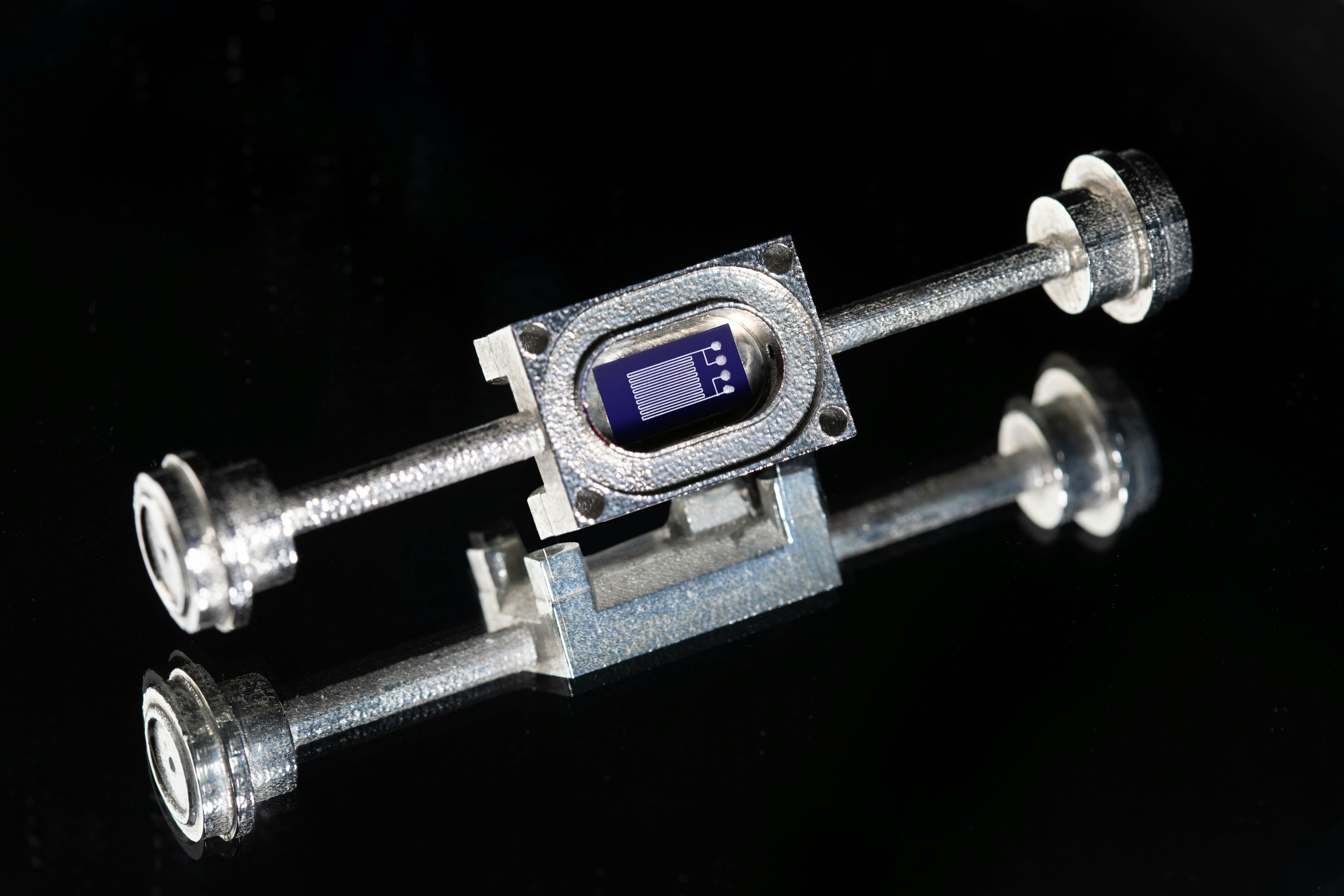

CERN plans to use the sensor-equipped pipes in the thermal control systems for the silicon detectors its engineers are currently developing. The detectors will be used to identify particles released from a multitude of collisions. Thanks to the pipes being created under AHEAD, the detectors’ thermal control systems will be able to run without the complicated cable set-up that’s usually required – thus saving space and allowing for better thermal control through temperature readings taken directly at strategic points. The new technology will also let engineers replace existing coolants with ones that are more effective and less damaging to the environment. “Technological breakthroughs are often needed before particle detectors can deliver the extraordinary performance that’s expected of them,” says Paolo Petagna, a CERN project manager. “These breakthroughs could lead to a totally new concept with applications well beyond the one originally intended, bringing benefits to important industries. That’s what we’re seeing with AHEAD.”

Pipes in orbit

One of the project’s key partners – Thales Alenia Space (TAS) – is studying how the sensor-equipped pipes could be employed in the International Space Station’s pressurized modules and in NASA’s future Lunar Gateway space station. TAS also plans to install the pipes in two-phase mechanically pumped fluid loops, which are a type of thermal control system used in its telecommunications satellites. Martin Raynaud, a thermal specialist at TAS, explains: “The lighter, more compact design enabled by the pipes, along with improved precision in temperature measurements and faster assembly, are key benefits for us. They allow for better thermal control, which is a critical factor in all space systems. That gives us a significant competitive advantage over rivals in Europe and the US.”

This project has received funding from ATTRACT, a European Union’s Horizon 2020 research and innovation project under grant agreement No 101004462. Consortium Partners are not responsible for any use that may be made of the results.