February 25, 2025

CSEM opens Switzerland’s first dry room to advance next-gen batteries

- CSEM has inaugurated a dry room unlike anything in the country, a start-of-the-art facility for assembling and prototyping cutting-edge batteries.

- Equipped with a pilot production line, this new infrastructure will play a crucial role in fast-tracking the commercialization of next-generation batteries.

- A dedicated section of the room is reserved for start-ups and small- and medium sized businesses (SMEs), providing them with strategic opportunities while lowering the risk and costs of innovation.

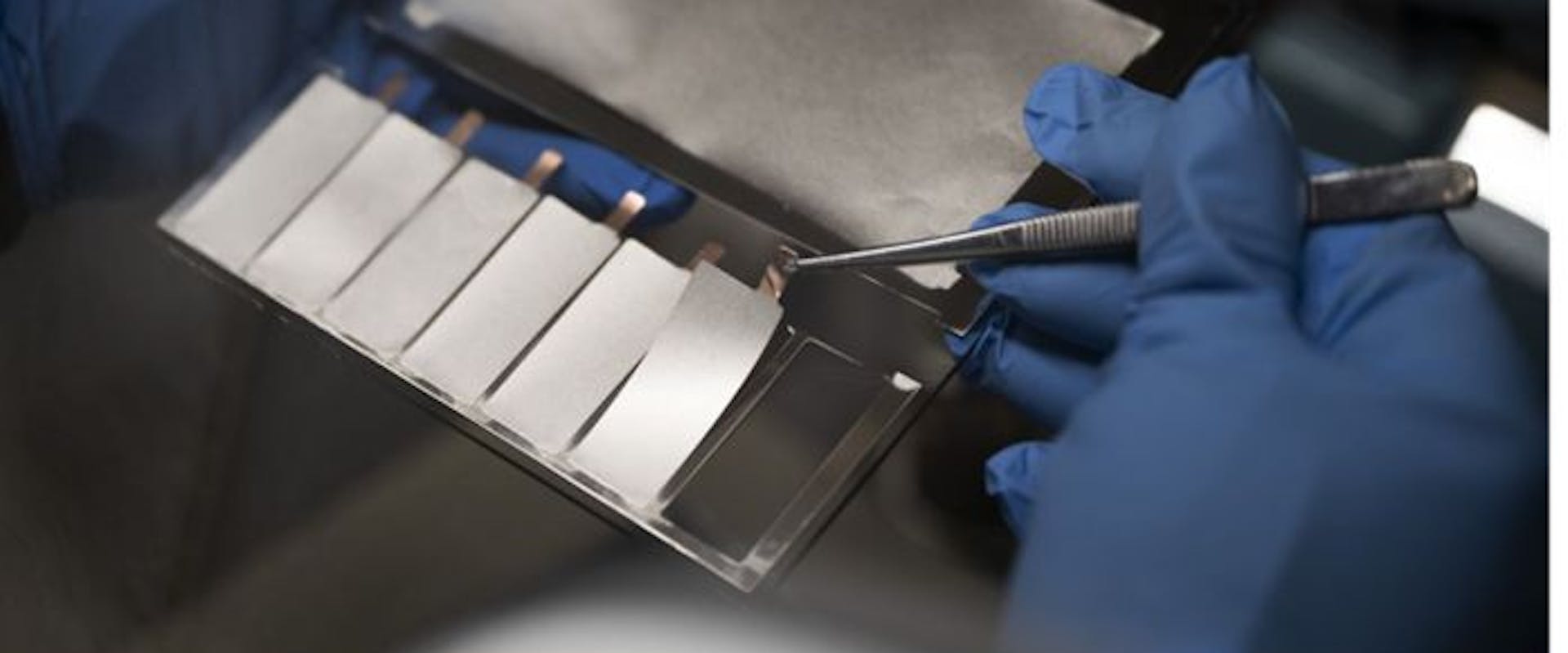

© Christian Beutler - A CSEM expert carefully unloads thin-film Li-metal anodes, deposited via thermal evaporation, onto a Cu current collector.