Curious to learn more about our industrial sensor technologies?

We understand the challenges and complexities of IoT deployment. Reach out now for expert guidance and take the first step towards smarter, more efficient, and robust IoT solutions.

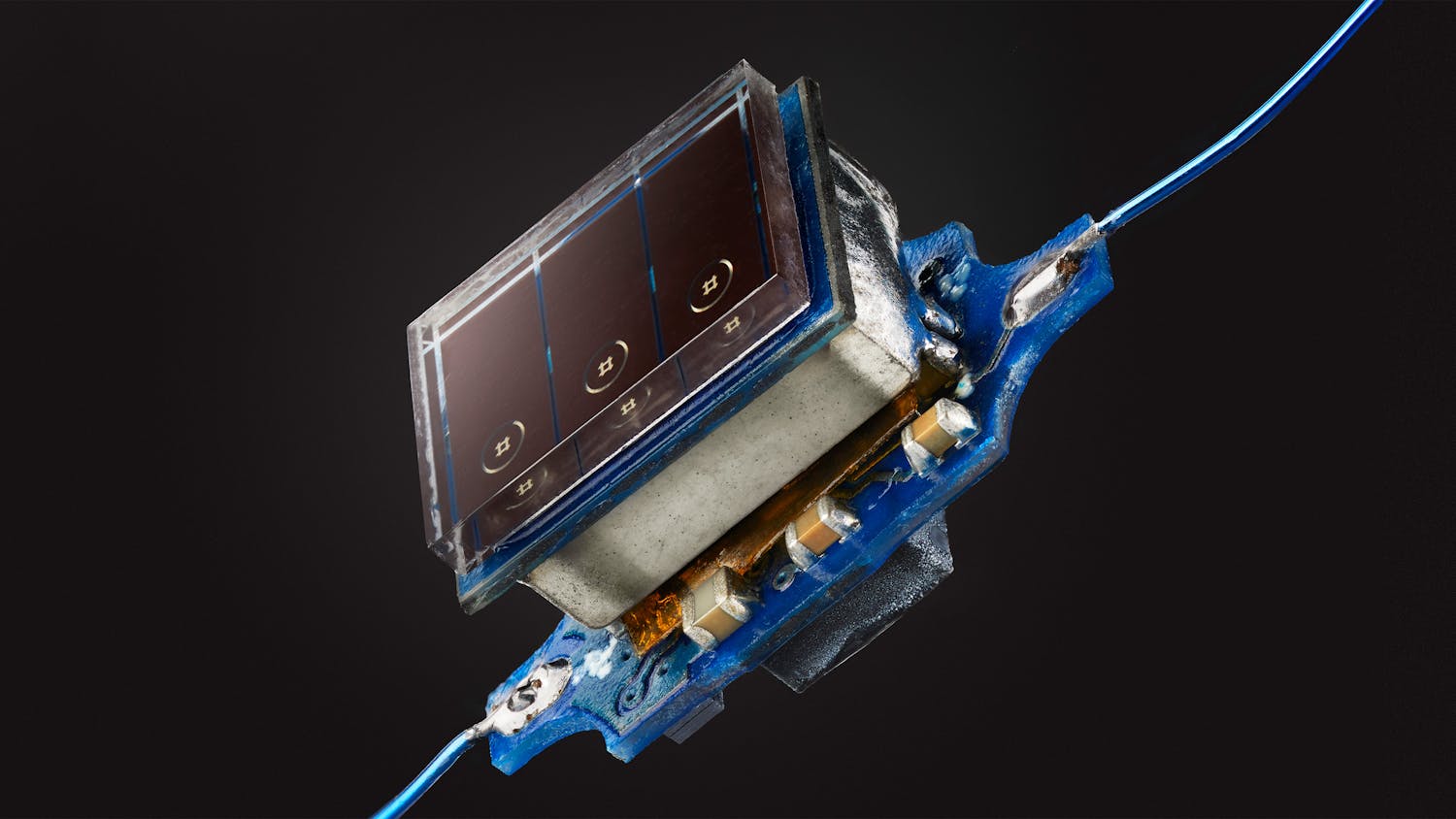

Reliable, compact, and secure sensing IoT solutions for industrial applications.

Today's remote sensing and actuating systems are widespread. From niche use cases, they have transitioned to pervasive deployment, bringing enhanced control, optimization, and safety. CSEM sensor technologies answer extreme expectations that commercially available products or traditional approaches don’t. Many challenges tied to the operating environment (e.g. temperature, obstacles to radio waves, biological tissues) and to the device (e.g. size, autonomy, cost, sensing strategy). This is precisely where an interdisciplinary team helps win the battle to bring a technically and commercially viable solution.

The pillars of CSEM IIoT solutions are:

The digitization trend pushes non-specialized industry to integrate wireless remote sensing into mechanical parts and assemblies to establish key differentiators. The sensing device must not interfere with operations, performances, and lifetime. Tight collaboration with the industrial partner is decisive in making integration of the sensor electronic a success in the production process.

Miniaturization of the sensing device is a key integration enabler which can be addressed via 2 approaches:

These approaches can be addressed successively in separate projects to accompany the industrial partner during volume ramp-up.

Wireless IoT devices need energy to operate. When not connected to the power network, they most often rely on batteries (primary cells) or on accumulators (secondary cells or supercapacitors) when they can harvest energy from the surrounding environment.

Batteries and other energy tanks constrain the power consumption profile of a system. Depending on their structure and chemistry, this results in maximum current peaks and duration, voltage drops, temperature range and dependence, self-discharge rate, and many other effects. To provide the most adequate solution for a specific application, we further characterize commercially available batteries with specific power consumption profiles. We also prototype with industrial prototypes from innovative battery companies and startups and which are close to industrial release (e.g. solid-state, sustainable). We have created and further expand a knowledge base critical to our customers.

An antenna, a key element of the communication chain, requires highly skilled craftsmanship to anticipate and counterbalance the possible negative impacts of the environment on propagation properties. Proper performance (e.g. range, directivity) requires integration in the system housing, surrounding components and circuit to be considered carefully. The environment in which the final product must operate is also desicive for the design. Buried devices, metallic environments and body implants are all examples of specific and sometimes complicated conditions requiring specific antenna design, system integration and characterization. The domain is counter-intuitive: sometimes even a keyhole in the housing or the limb of a human being can be used as the radiating structure.

We leverage our EM specialists and fully equipped laboratories to help industrial partners with their Bluetooth, LoRa and UWB challenges and to explore new approaches to improve wireless link performances.

Electromagnetic (EM) computation

Prototyping

Characterization

Optimization and fine tuning

Ready solutions

We understand the challenges and complexities of IoT deployment. Reach out now for expert guidance and take the first step towards smarter, more efficient, and robust IoT solutions.