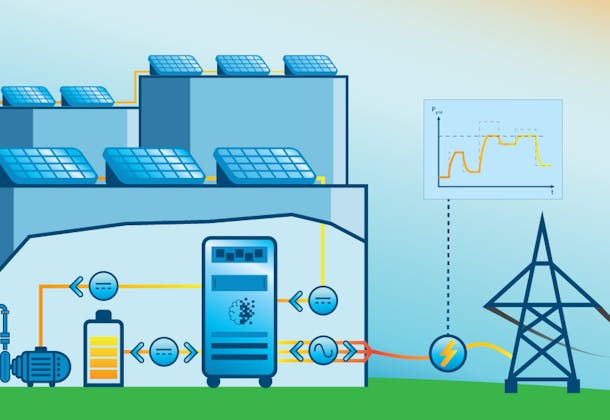

Battery applied research and expertise

(Cet article n'est disponible qu'en anglais)

Expertise ranging from materials to systems. Batteries are a key component in tackling the social and economic challenges that are unfolding as part of the energy transition. Nowadays, electrochemical storage systems have the ability to store electrical energy for decentralized stationary and mobile applications.