Breathable, washable, and digitally customizable

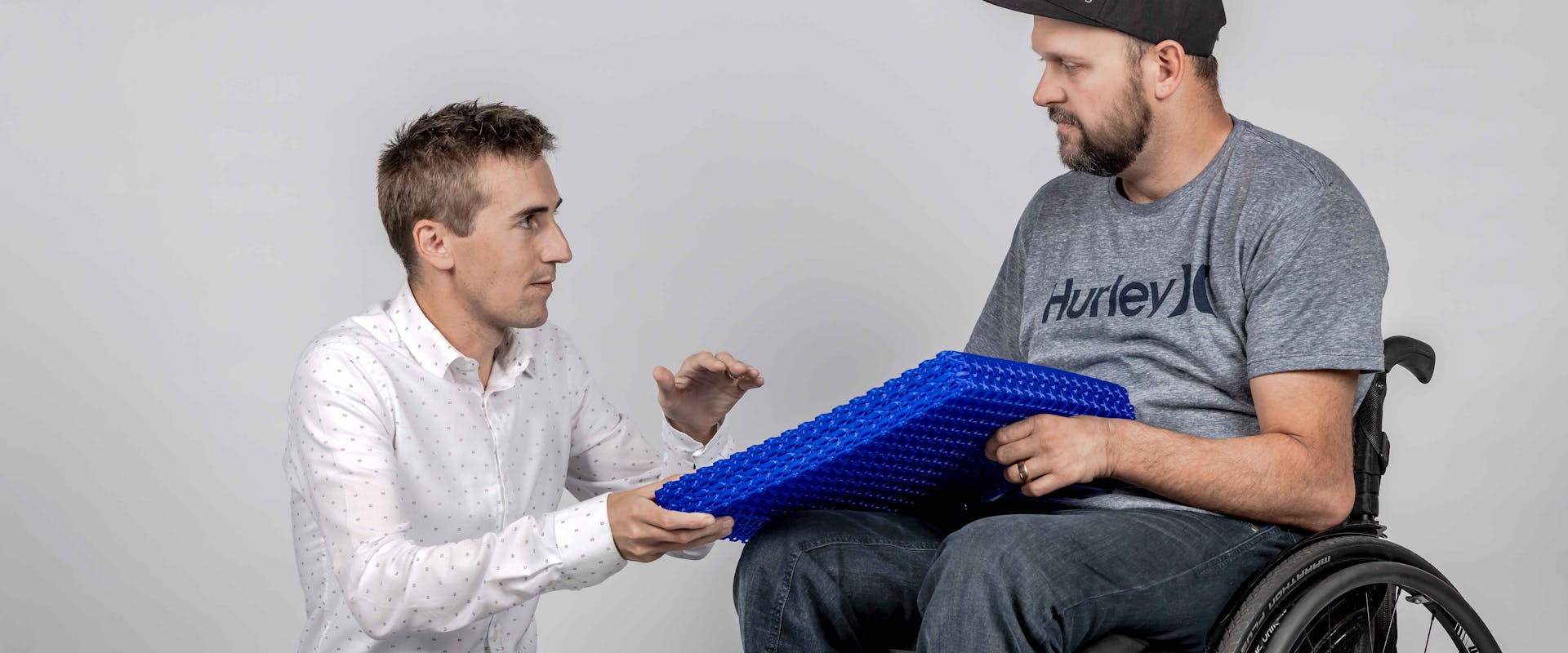

Custom-made support cushions and seat cushions play an important role in preventing pressure injuries, and related health issues in individuals who require them. However, until now the manufacturing process has been extremely laborious and expensive, with cushions being made individually by hand. Additionally, cleaning them can be challenging, which makes them less sanitary. "We collaborated closely with Andreas Gautschi, a project manager with the SPS and a wheelchair-using individual, to test whether – and how – we could print this type of cushion with an open-cell structure," continues Christoph Joder. To do this, they digitized an existing custom-made cushion, remodeled it on-screen and printed it.

The results were undeniable: Printed cushions have a consistent open cell structure, giving them better moisture-wicking and temperature-regulating properties than a conventional cushion. Printed versions are also easy to wash. In addition, the traceability of changes is hugely valuable from a regulatory point of view. However, the first prototype was still too heavy, and it took too long to print. Christoph Joder and his team therefore made selective adjustments to the structure keeping in mind the needs of all individuals and were able to eliminate these problems. "We are very proud of what we were able to achieve with the current design and are grateful for the immediately positive feedback we have received from everyone."