5 décembre 2024

Pietro Iurilli receives the prestigious Battery Young Researcher Award

(Anglais uniquement)

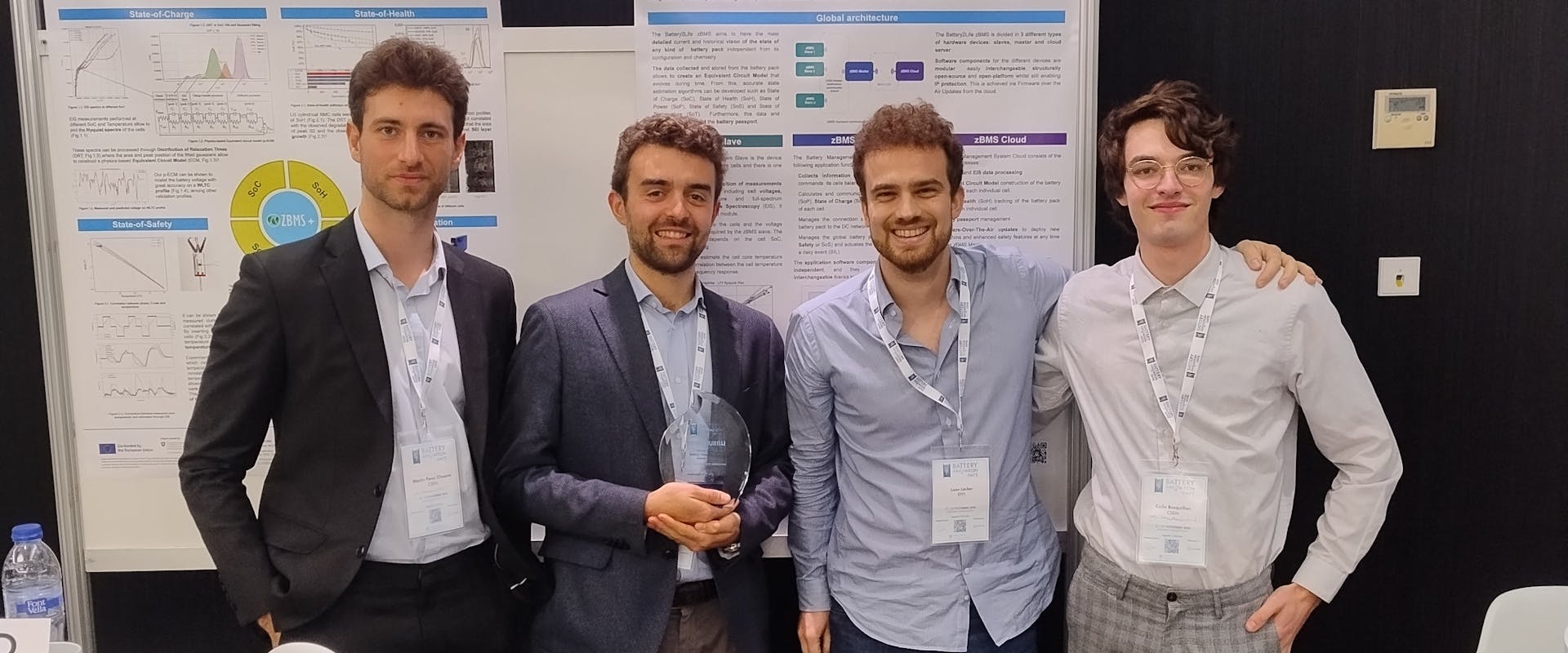

This year, Pietro Iurilli, who completed his PhD at CSEM in collaboration with ETH Zürich, was honored for his pioneering research on leveraging Electrochemical Impedance Spectroscopy (EIS) to model and monitor the aging of lithium-ion batteries.

©CSEM - Left to right: Martin Perez Chuecos, Battery BMS Software Architect & Developer at CSEM; the awardee Pietro Iurilli; Leon Locher, Battery BMS Software Developer; and Colin Bocquillon, Battery BMS Hardware Developer at CSEM.